The formalin production industry is a crucial segment within the chemical sector, contributing significantly to various applications, from manufacturing to healthcare. Understanding the cost analysis of formalin production is vital for businesses aiming to delve into this field or those seeking detailed insights to enhance their existing operations. In this comprehensive report, we'll explore the procurement resource assessment, product definition, market drivers, and the economic dynamics influencing formalin production.

Introduction

Formalin, a key chemical widely used in various industries, is a solution of formaldehyde gas dissolved in water. The production process involves several stages and resources, making a cost analysis imperative for businesses. Analyzing the expenses incurred in producing formalin enables companies to strategize effectively and make informed decisions to optimize their production processes and maintain competitive pricing.

Request For Free Sample: https://www.procurementresource.com/production-cost-report-store/formalin/request-sample

Procurement Resource Assessment of Formalin Production Process

The procurement resource assessment of the formalin production process involves an in-depth evaluation of the resources required. This includes the raw materials such as methanol, which is a primary component, along with other catalysts and necessary utilities. The cost of acquiring these resources, their availability, quality, and market fluctuations significantly impact the overall cost of production.

Additionally, the procurement resource assessment encompasses the examination of production equipment, technology, and labor costs. Investing in efficient equipment and adopting advanced technology can streamline the production process, thereby impacting the overall cost. Labor costs, including skilled technicians and operational staff, also play a crucial role in the cost analysis.

Product Definition

Formalin is a versatile chemical compound used in various applications, including adhesives, disinfectants, and preservatives. The product definition in the cost analysis report focuses on the specifications of the formalin produced, ensuring it meets industry standards and requirements. Analyzing the grade, concentration, and purity of the formalin manufactured is essential to understand its market value and applications in different sectors.

Market Drivers

Understanding the market drivers influencing formalin production is pivotal for businesses seeking to enter or expand in this industry. Several factors contribute to the market dynamics, including:

Demand and Applications: The demand for formalin is directly linked to its applications in diverse industries, such as healthcare, agriculture, and manufacturing. A comprehensive report would analyze these sectors and forecast the future demand for formalin.

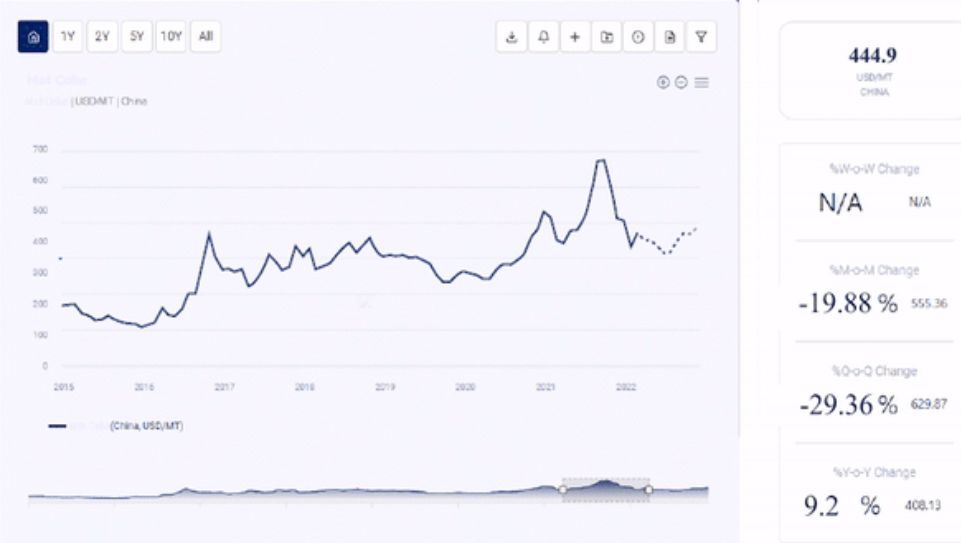

Raw Material Prices: The fluctuating prices of raw materials, especially methanol, heavily influence the production cost. A detailed cost analysis report should cover the trends and forecasts of these prices to anticipate their impact on formalin production.

Regulatory Environment: Regulatory policies and environmental standards play a crucial role in the formalin production industry. Compliance with regulations impacts production processes and costs. An extensive report should outline these regulations and their effects on the cost structure.

Unveiling the Economics of Formalin Production

The economics of formalin production involves a detailed cost breakdown of each stage in the production process. This includes the cost of raw materials, energy consumption, labor expenses, equipment depreciation, maintenance, and overheads. An in-depth analysis reveals the cost drivers and areas where optimization can be implemented to improve efficiency and reduce overall production costs.

Looking for an Exhaustive and Personalized Report

Businesses seeking to enter or expand within the formalin production industry must obtain a comprehensive, personalized cost analysis report to substantiate their strategies. An exhaustive report includes detailed insights, market forecasts, and strategic recommendations tailored to the specific needs of the business. This report serves as a valuable tool to make informed decisions and enhance the competitive edge in the market.

In conclusion, a thorough cost analysis report of formalin production processes provides businesses with a strategic advantage, allowing them to optimize production, make informed decisions, and stay ahead in a competitive market. Investing in a detailed and personalized report is essential for businesses looking to establish or improve their position within the formalin production industry.

The food industry utilises aluminium sulphate as a firming agent, and animal feed uses it as a bactericide, which have an impact on its pricing trends.

The food industry utilises aluminium sulphate as a firming agent, and animal feed uses it as a bactericide, which have an impact on its pricing trends.