Chlorine is a chemical element denoted by the symbol Cl. It has an atomic number of 17 and an atomic weight that fluctuates from 35.446 g/mol to 35.457 g/mol.

Chlorine has a melting point of 103 °C (153 °F) and a boiling temperature of 34 °C (29 °F). It has a density of 3.214 g/litre (0.429 ounce/gallon).

It is the second-lightest member of the periodic table's halogen elements, or group 17. It is a hazardous greenish-yellow gas found in nature. It is a gas that is unpleasant to the eyes and respiratory system.

Request for Real Time Chlorine Prices: https://www.procurementresource.com/resource-center/chlorine-price-trends/pricerequest

It has the electronic structure [Ne] 3s²3p⁵. It has a strong suffocating odour. It is created through the electrolysis of salt and the chloralkali process.

Canada, the United States, France, Japan, and Belgium are the leading chlorine producing countries across the globe.

Key Details About the Chlorine Price Trend:

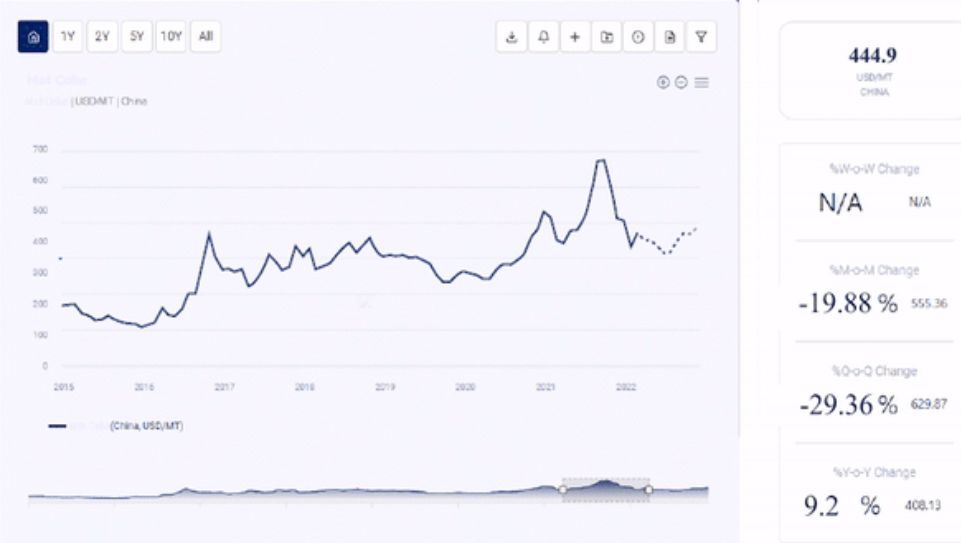

Procurement Resource does an in-depth analysis of the price trend to bring forth the monthly, quarterly, half-yearly, and yearly information on the Chlorine price in its latest pricing dashboard. The detailed assessment deeply explores the facts about the product, price change over the weeks, months, and years, key players, industrial uses, and drivers propelling the market and price trends.

Each price record is linked to an easy-to-use graphing device dated back to 2014, which offers a series of functionalities; customization of price currencies and units and downloading of price information as Excel files that can be used offline.

The Chlorine Price chart, including India Chlorine price, USA Chlorine price, pricing database, and analysis can prove valuable for procurement managers, directors, and decision-makers to build up their strongly backed-up strategic insights to attain progress and profitability in the business.

Industrial Uses Impacting Chlorine Price Trend:

It is used to purify drinking water as well as swimming pool water. It is also used to kill bacteria and pathogens as a disinfectant.

It is used to purify drinking water as well as swimming pool water. It is also used to kill bacteria and pathogens as a disinfectant.

It is also used in the manufacture of PVC. It's also used in window frames, automobile interiors, electrical wiring insulation, water pipes, blood bags, and vinyl flooring.

Aside from that, it is widely utilised in organic chemistry. It is also used in substitution reactions as an oxidising agent.

Furthermore, it is used in the pharmaceutical and nutraceutical businesses. It is also used in the paper and pulp producing sectors.

Furthermore, it is employed in the production of numerous medications as well as in the mining sector. It is also used as an antiseptic.

Key Players:

- Nouryon

- Ercros S.A

- Olin Corporation

- Occidental Petroleum Corporation (OxyChem)

Recent Development:

- 05 April 2023: European chlorine production in February 2023 reached 612, 381 tonnes. The average daily output was 14.8% greater than the previous month but around 21.0 percent lower than in February 2022.

Related Post:

- https://famoushindiblog.school.blog/2023/04/26/aluminum-prices-and-forecasts-provided-by-procurement-resource/

- https://procurementresource.blogspot.com/2023/04/calcium-carbonate-prices-latest-price.html

- https://www.marketreport.us/butadiene-prices-trend/

- https://www.marketreport.us/2-ethylhexanol-prices/

- https://www.marketreport.us/amoxicillin-prices-trend/

- https://www.marketsize.us/2023/04/21/broccoli-powder-prices-trend/

About Us:

Procurement Resource offers in-depth research on product pricing and market insights for more than 500 chemicals, commodities, and utilities updated daily, weekly, monthly, and annually. It is a cost-effective, one-stop solution for all your market research requirements, irrespective of which part of the value chain you represent.

We have a team of highly experienced analysts who perform comprehensive research to deliver our clients the newest and most up-to-date market reports, cost models, price analysis, benchmarking, and category insights, which help in streamlining the procurement process for our clientele. Our team tracks the prices and production costs of a wide variety of goods and commodities, hence providing you with the latest and consistent data.

To get real-time facts and insights to help our customers, we work with a varied range of procurement teams across industries. At Procurement Resource, we support our clients, with up-to-date and pioneering practices in the industry, to understand procurement methods, supply chain, and industry trends, so that they can build strategies to achieve maximum growth.

Contact Us:

Company Name: Procurement Resource

Contact Person: Jolie Alexa

Email: sales@procurementresource.com

Toll Free Number: USA & Canada – Phone no: +1 307 363 1045 | UK – Phone no: +44 7537 132103 | Asia-Pacific (APAC) – Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA