| Product Name | Depreciation Rates |

| Region/Countries for which Data is available |

|

| Currency | US$ (Data can also be provided in local currency) |

| Supplier Database Availability | Yes |

| Customization Scope | Our services can be customized as per the requirements of the customer |

| Post-Sale Analyst Support | 360-degree analyst support after service delivery |

Request for Real Time Depreciation Rates Prices: https://www.procurementresource.com/resource-center/depreciation-rates-price-trends/pricerequest

The percentage of an extended investment that a company or an individual utilize as a yearly tax-deductible expense over the period through which it is claimed as a tax deduction is known as depreciation rate. It can also be defined as the percentage of a prolonged investment made on an asset by an organization that it may claim as a tax-deductible expenditure throughout the useful life of asset. This is different for all classes of assets.

The company gets a clearer picture of how it spends as compared to its earnings by dividing the cost over several accounting periods. Depreciation rates also guarantees that the company’s accounting conforms with national rules for assessing depreciation.

The most conventional and simple way to evaluate depreciation is known as “straight line depreciation,” as it is based on the theory that the utilization and value the company or the individual get from the asset will be more or less consistent during each of the years they would use it.

Though there are several countries that have depreciation rates systems however the popular ones are the United States, Argentina, Australia, Austria, Germany, New Zealand, Brazil, Canada, France, Japan, India, and Russia.

Key Details About the Depreciation Rates Price Trend:

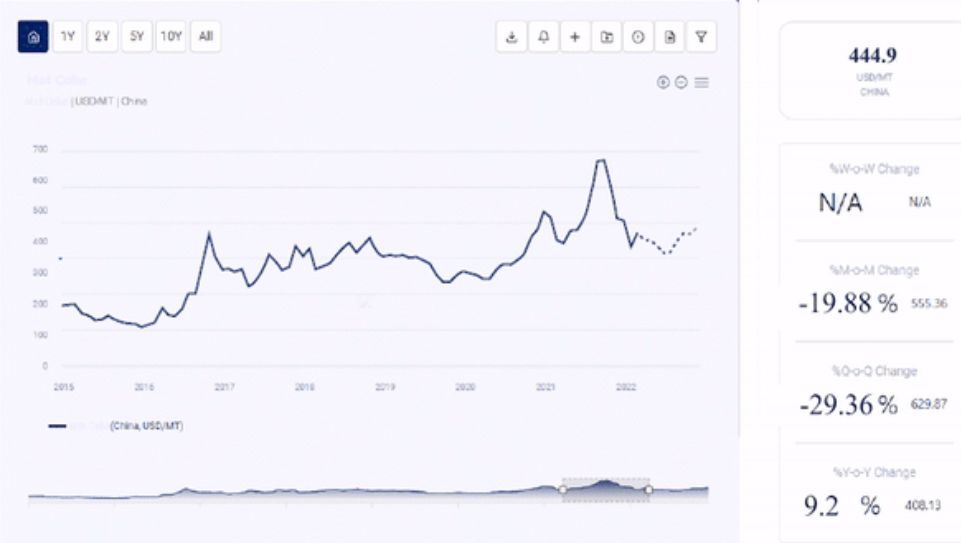

Procurement Resource does an in-depth analysis of the price trend to bring forth the monthly, quarterly, half-yearly, and yearly information on the Depreciation Rates price in its latest pricing dashboard. The detailed assessment deeply explores the facts about the product, price change over the weeks, months, and years, key players, industrial uses, and drivers propelling the market and price trends.

Each price record is linked to an easy-to-use graphing device dated back to 2014, which offers a series of functionalities; customization of price currencies and units and downloading of price information as excel files that can be used offline.

The Depreciation Rates price Trend, chart, pricing database, and analysis can prove valuable for the procurement managers, directors, and decision-makers to build up their strongly backed up strategic insights to attain progress and profitability in the business.

Industrial Uses Impacting Depreciation Rates Price Trend:

There are several uses of Depreciation Rates for big and small businesses since they purchase large lump sums of quantifiable resources and properties, such as buildings, equipment, vehicles and so on. It assists businesses match up with their revenues with expenditures, comprising of those assets that are utilised to make revenues.

Key Market Players:

- com

- Bank of America Corp.

- Centurylink

- Delta Air Lines

- EOG Resources

- FedEx

News and Events:

- May 28, 2022 – There is no revelation or exposure about software depreciation useful lives in the 2021 annual reports of organisations such as Amazon, Facebook, Netflix, as well as Google and NVIDIA. Besides, none of these companies said that they do not benefit from any software development costs or did not reveal any specifics at all.

Related Reports:

- Rice Price: https://www.marketwatch.com/press-release/rice-price-history-and-forecast-analysis-provided-by-procurement-resource-2022-10-14

- Soybean Oil Prices: https://www.marketwatch.com/press-release/soybean-oil-price-chart-historical-and-forecast-analysis-provided-by-procurement-resource-2022-10-14

- Steel Prices: https://www.marketwatch.com/press-release/steel-price-history-and-forecast-analysis-provided-by-procurement-resource-2022-10-14

- Tin Prices: https://www.marketwatch.com/press-release/tin-prices-trend-forecasts-provided-by-procurement-resource-2022-10-17

- Urea Prices: https://www.marketwatch.com/press-release/urea-prices-today-price-chart-and-forecast-analysis-provided-by-procurement-resource-2022-10-17

- Sunflower Oil Prices: https://www.marketwatch.com/press-release/sunflower-oil-price-trend-analysis-historical-chart-and-forecast-2022-10-17

- Titanium Prices: https://www.marketwatch.com/press-release/titanium-price-chart-historical-and-forecast-analysis-provided-by-procurement-resource-2022-10-17

- Acetylene Prices: https://www.marketwatch.com/press-release/acetylene-prices-today-price-chart-and-forecast-analysis-provided-by-procurement-resource-2022-10-17

About Us:

Procurement Resource offers in-depth research on product pricing and market insights for more than 500 chemicals, commodities, and utilities updated daily, weekly, monthly, and annually. It is a cost-effective, one-stop solution for all your market research requirements, irrespective of which part of the value chain you represent.

We have a team of highly experienced analysts who perform comprehensive research to deliver our clients the newest and up-to-date market reports, cost models, price analysis, benchmarking, and category insights, which help in streamlining the procurement process for our clientele. Our team track the prices and production costs of a wide variety of goods and commodities, hence, providing you with the latest and consistent data.

To get real-time facts and insights to help our customers, we work with a varied range of procurement teams across industries. At Procurement Resource, we support our clients, with up-to-date and pioneering practices in the industry, to understand procurement methods, supply chain, and industry trends, so that they can build strategies to achieve maximum growth.

Contact Us:

Company Name: Procurement Resource

Contact Person: Jolie Alexa

Email: sales@procurementresource.com

Toll Free Number: USA & Canada - Phone no: +1 307 363 1045 | UK - Phone no: +44 7537 132103 | Asia-Pacific (APAC) - Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA