| Product Name | Protactinium |

| HS Code | 28442000 |

| Chemical Formula | PA |

| Synonyms | 7440-13-3, Protactinium |

| Region/Countries for which Data is available |

|

| Currency | US$ (Data can also be provided in local currency) |

| Supplier Database Availability | Yes |

| Customization Scope | Our services can be customized as per the requirements of the customer |

| Post-Sale Analyst Support | 360-degree analyst support after service delivery |

Request for Real Time Protactinium Prices: https://www.procurementresource.com/resource-center/paprotactinium-price-trends/pricerequest

The chemical element Protactinium, a silvery-gray material, has an atomic number of 91. It is a dense actinide metal that easily interacts with oxygen, water vapour, and inorganic acids to produce a variety of chemical compounds. Among +4, +3, and +2 states, protactinium is typically found in the +5-oxidation state.

Protactinium is not widely distributed throughout the Earth’s crust. Due to its high radioactivity, it is examined for a variety of research reasons, just like other metals. Protactinium’s atomic number is 91 and it is denoted by Pa. Also, the major amounts of protactinium are present in the ores of uranium.

The reduction process of fluoride is used to create PA (Protactinium). In this procedure, the fluoride (protactinium tetrafluoride or protactinium pentafluoride) is reduced with calcium, lithium, or barium at a temperature of 1300–1400 °C to produce PA (Protactinium) metal.

The protactinium-producing countries are Kazakhstan, Canada, Australia, China, and India.

Key Details About the PA (Protactinium) Price Trend:

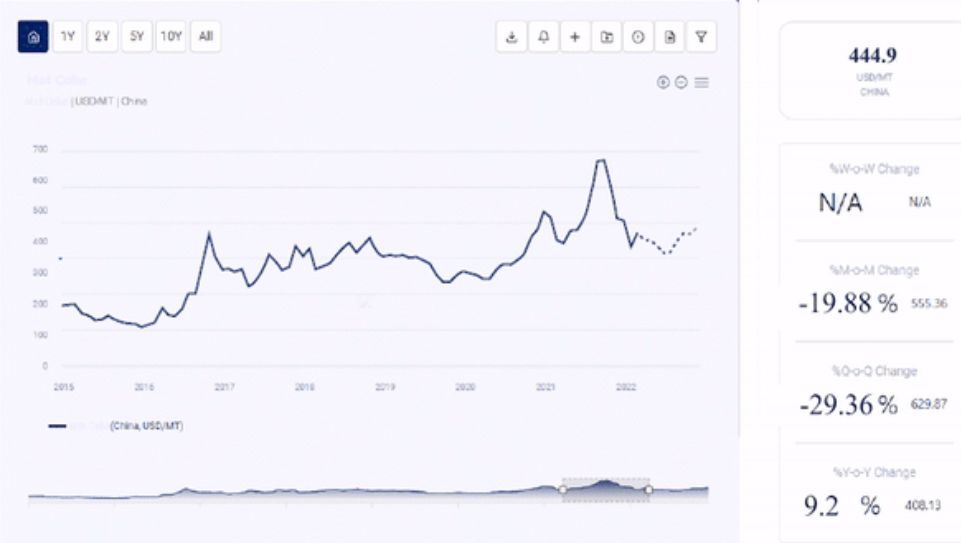

Procurement Resource does an in-depth analysis of the price trend to bring forth the monthly, quarterly, half-yearly, and yearly information on the PA (Protactinium) price in its latest pricing dashboard. The detailed assessment deeply explores the facts about the product, price change over the weeks, months, and years, key players, industrial uses, and drivers propelling the market and price trends.

Each price record is linked to an easy-to-use graphing device dated back to 2014, which offers a series of functionalities; customization of price currencies and units and downloading of price information as excel files that can be used offline.

The PA (Protactinium) Price chart, pricing database, and analysis can prove valuable for procurement managers, directors, and decision-makers to build up their strongly backed-up strategic insights to attain progress and profitability in the business.

Industrial Uses Impacting PA (Protactinium) Price Trend:

The PA (Protactinium) price trend is influenced by its industrial application which includes only basic scientific research because of the products’ scarcity, high radioactivity, and toxic nature.

Key Market Players:

- American Elements

- Lenntech B.V

News and Events:

- July 27, 2022 – As per the information communicated by Jitendra Singh, Minister of State in the Prime Minister’s Office, around 8,813 tonnes of uranium oxide deposits were discovered by the Atomic Minerals Directorate for Exploration and Research (AMD) in Rohil in Sikar district, and 1,086 tonnes in Rohil west, 3,570 tonnes in Jahaz as well as 1,002 tonnes in Geratiyon ki Dhani.

Related Reports:

- Nickel Price Trend – https://www.procurementresource.com/resource-center/nickel-price-trends

- Steel Price Trend – https://www.procurementresource.com/resource-center/steel-price-trends

- Coal Price Trend – https://www.procurementresource.com/resource-center/coal-price-trends

About Us:

Procurement Resource offers in-depth research on product pricing and market insights for more than 500 chemicals, commodities, and utilities updated daily, weekly, monthly, and annually. It is a cost-effective, one-stop solution for all your market research requirements, irrespective of which part of the value chain you represent. We have a team of highly experienced analysts who perform comprehensive research to deliver our clients the newest and most up-to-date market reports, cost models, price analysis, benchmarking, and category insights, which help in streamlining the procurement process for our clientele. Our team track the prices and production costs of a wide variety of goods and commodities, hence, providing you with the latest and consistent data.

To get real-time facts and insights to help our customers, we work with a varied range of procurement teams across industries. At Procurement Resource, we support our clients, with up-to-date and pioneering practices in the industry, to understand procurement methods, supply chain, and industry trends, so that they can build strategies to achieve maximum growth.

Contact Us:

Company Name: Procurement Resource

Contact Person: Chris Byrd

Email: sales@procurementresource.com

Toll Free Number: USA & Canada – Phone no: +1 307 363 1045 | UK – Phone no: +44 7537 132103 | Asia-Pacific (APAC) – Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA