The latest report titled “Cement manufacturing” by Procurement Resource a global procurement research and consulting firm, provides an in-depth cost analysis of the manufacturing process of Cement.Procurement Resource study is based on the latest prices and other economic data available. It also offers additional analysis of the report with detailed breakdown of all cost components (capital investment details, manufacturing cost details, economics...

Sunday, April 2, 2023

10:55 PM

10:55 PM Jolie Alexa

Jolie Alexa No comments

No comments

The latest report titled “Cheese manufacturing” by Procurement Resource a global procurement research and consulting firm, provides an in-depth cost analysis of the manufacturing process of Cheese.Procurement Resource study is based on the latest prices and other economic data available. It also offers additional analysis of the report with detailed breakdown of all cost components (capital investment details, manufacturing cost details, economics...

Friday, March 31, 2023

12:20 AM

12:20 AM Jolie Alexa

Jolie Alexa No comments

No comments

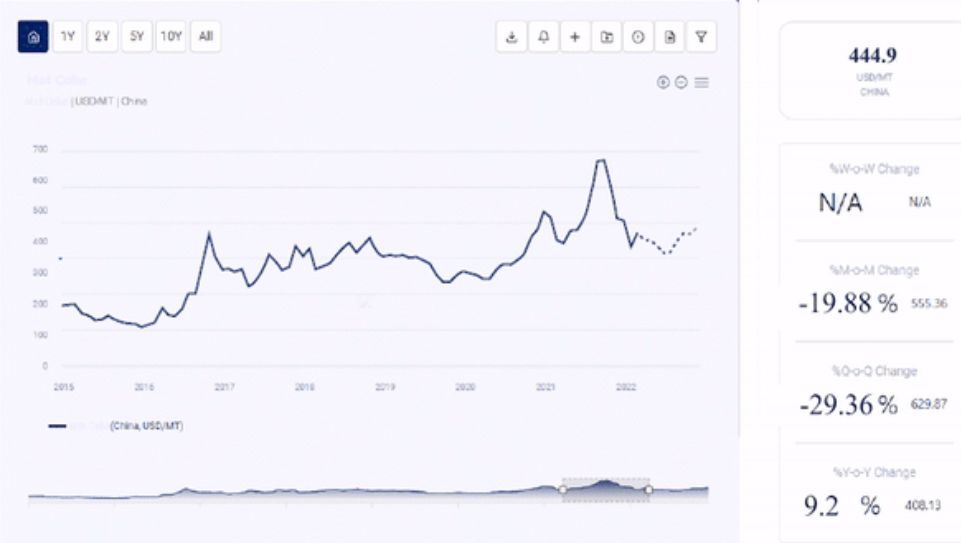

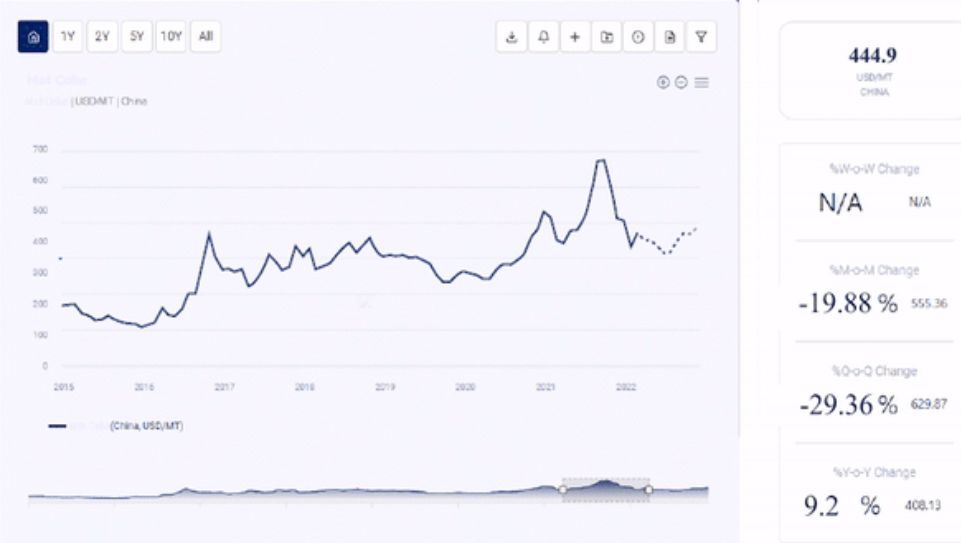

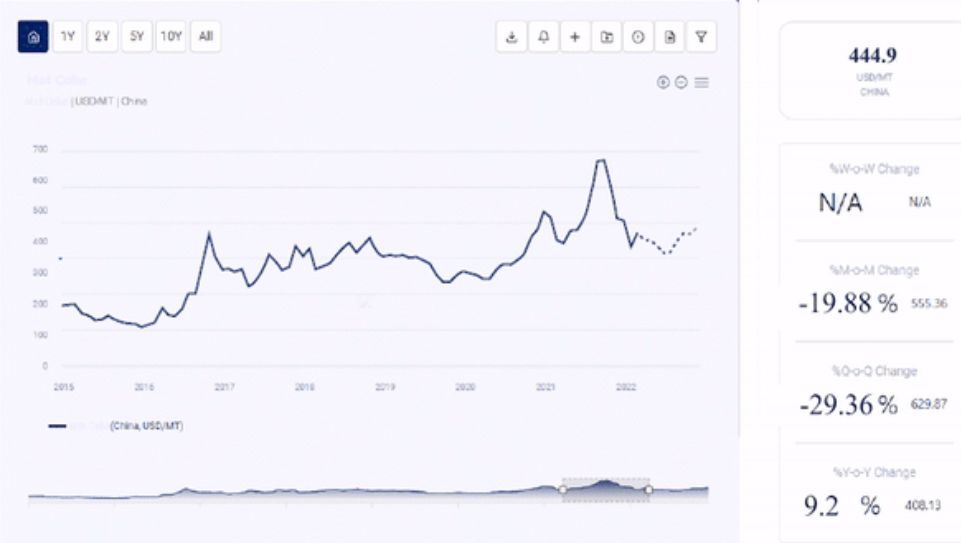

The latest report titled “Coffee manufacturing” by Procurement Resource a global procurement research and consulting firm, provides an in-depth cost analysis of the manufacturing process of Coffee.Procurement Resource study is based on the latest prices and other economic data available. It also offers additional analysis of the report with detailed breakdown of all cost components (capital investment details, manufacturing cost details, economics...

12:07 AM

12:07 AM Jolie Alexa

Jolie Alexa No comments

No comments

The latest report titled “Coal manufacturing” by Procurement Resource a global procurement research and consulting firm, provides an in-depth cost analysis of the manufacturing process of Coal.Procurement Resource study is based on the latest prices and other economic data available. It also offers additional analysis of the report with detailed breakdown of all cost components (capital investment details, manufacturing cost details, economics for...

12:03 AM

12:03 AM Jolie Alexa

Jolie Alexa No comments

No comments

Report FeaturesDetailsProduct NameBase OilRegion/Countries CoveredAsia Pacific: China, India, Indonesia, Pakistan, Bangladesh, Japan, Philippines, Vietnam, Iran, Thailand, South Korea, Iraq, Saudi Arabia, Malaysia, Nepal, Taiwan, Sri Lanka, UAE, Israel, Hongkong, Singapore, Oman, Kuwait, Qatar, Australia, and New ZealandEurope: Germany, France, United Kingdom,...

Thursday, March 30, 2023

11:57 PM

11:57 PM Jolie Alexa

Jolie Alexa No comments

No comments

4A zeolite is a calcium, sodium, or hydrated crystalline silicate of aluminium. The structure of 4A zeolite is similar to that of zeolite A. In its natural or synthetic form, it can be used as a detergent builder, cracking catalyst, and water softener.Request for Real Time 4A Zeolite Prices: https://www.procurementresource.com/resource-center/4-a-zeolite-price-trends/pricerequestIt...

11:53 PM

11:53 PM Jolie Alexa

Jolie Alexa No comments

No comments

Report FeaturesDetailsProduct NameChloroformRegion/Countries CoveredAsia Pacific: China, India, Indonesia, Pakistan, Bangladesh, Japan, Philippines, Vietnam, Iran, Thailand, South Korea, Iraq, Saudi Arabia, Malaysia, Nepal, Taiwan, Sri Lanka, UAE, Israel, Hongkong, Singapore, Oman, Kuwait, Qatar, Australia, and New ZealandEurope: Germany, France, United Kingdom,...

Subscribe to:

Posts (Atom)

%20Price%20Trend.png)