The latest report titled “Acetone, or Propanone Production Cost Report” by Procurement Resource a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Acetone, or Propanone.Report FeaturesDetailsProduct NameAcetone, or PropanoneProcess IncludedAcetone or Propanone From Propylene-Direct OxidationAcetone or Propanone Production From Propylene- Indirect OxidationAcetone or Propanone...

Monday, March 6, 2023

11:50 PM

11:50 PM Jolie Alexa

Jolie Alexa No comments

No comments

The latest report titled “4A Zeolite Production Cost Report” by Procurement Resource a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the 4A Zeolite.Report FeaturesDetailsProduct Name4A ZeoliteProcess Included4A Zeolite Production From Iraqi Kaolin via Ion Exchange Technique4A Zeolite Production From a Sodium Aluminate Solution Segments CoveredManufacturing Process:...

Sunday, March 5, 2023

10:59 PM

10:59 PM Jolie Alexa

Jolie Alexa No comments

No comments

The latest report titled “Acetaldehyde Production Cost Report” by Procurement Resource a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Acetaldehyde.Report FeaturesDetailsProduct NameAcetaldehydeProcess IncludedAcetaldehyde From EthyleneAcetaldehyde Production From EthanolAcetaldehyde Production From AcetyleneSegments CoveredManufacturing Process: Process Flow, Material Flow,...

10:49 PM

10:49 PM Jolie Alexa

Jolie Alexa No comments

No comments

The latest report titled “3-Propenol Production Cost Report” by Procurement Resource a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the 3-Propenol.Report FeaturesDetailsProduct Name3-PropenolProcess Included3-Propenol Production From Propylene Oxide via Rearrangement3-Propenol Production From Propanol via Dehydrogenation3-propenol Production From Allyl Chloride via HydrolysisSegments...

10:41 PM

10:41 PM Jolie Alexa

Jolie Alexa No comments

No comments

The latest report titled “5-Nonanone Production Cost Report” by Procurement Resource a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the 5-Nonanone.Report FeaturesDetailsProduct Name5-NonanoneProcess Included5-Nonanone Production From Levulinic Acid (LA) via Catalytic Processing Segments CoveredManufacturing Process: Process Flow, Material Flow, Material BalanceRaw...

10:28 PM

10:28 PM Jolie Alexa

Jolie Alexa No comments

No comments

The latest report titled “Acetaminophen Production Cost Report” by Procurement Resource a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of the Acetaminophen.Report FeaturesDetailsProduct NameAcetaminophenProcess IncludedAcetaminophen Production From PhenolSegments CoveredManufacturing Process: Process Flow, Material Flow, Material BalanceRaw Material and Product/s Specifications:...

Thursday, March 2, 2023

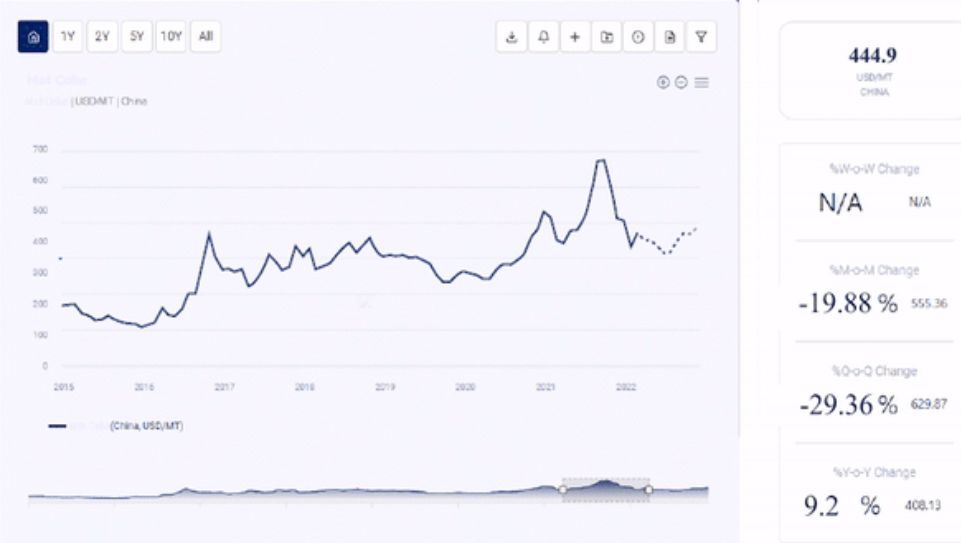

Report FeaturesDetailsProduct NameOlive OilRegion/Countries CoveredAsia Pacific: China, India, Indonesia, Pakistan, Bangladesh, Japan, Philippines, Vietnam, Iran, Thailand, South Korea, Iraq, Saudi Arabia, Malaysia, Nepal, Taiwan, Sri Lanka, UAE, Israel, Hongkong, Singapore, Oman, Kuwait, Qatar, Australia, and New ZealandEurope: Germany, France, United Kingdom,...

Subscribe to:

Posts (Atom)

%20Price%20Trend.png)