| Report Features | Details |

| Product Name | Steel |

| Region/Countries Covered |

|

| Currency | US$ (Data can also be provided in local currency) |

| Customization Scope | The report can be customized as per the requirements of the customer |

| Post-Sale Analyst Support | 360-degree analyst support after report delivery |

Request for Real Time Steel Prices: https://www.procurementresource.com/resource-center/steel-price-trends/pricerequest

Steel is an iron alloy (The base metal of steel is iron) of carbon, chromium, and iron. Due to it being cost-efficient and having high tensile strength, it is used extensively in infrastructure, ships, automobiles, buildings, tools, trains, machines, weapons, and appliances, among others.

It comes in two different shapes, face-centered cubic, and body-centered cubic, depending on the temperature. Iron becomes steel when carbon, recycled steel, and trace amounts of other components are added.

Less than 2% of the components are carbon, 2% are manganese, and phosphorus, oxygen, silicon, and sulphur are present at trace levels. Stainless steel has an additional 22 percent chromium and is resistant to oxidation and corrosion.

China, Japan, Germany, South Korea, and Russia are the leading Steel producing countries globally.

Key Details About the Steel Price Trend:

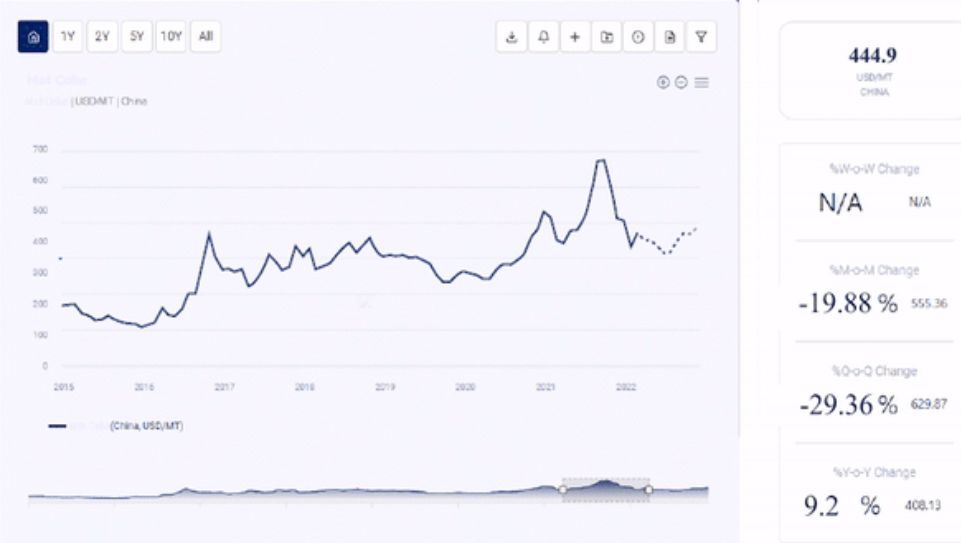

Procurement Resource does an in-depth analysis of the price trend to bring forth the monthly, quarterly, half-yearly, and yearly information on the Steel price, zinc price, aluminum price, etc. in its latest pricing dashboard. The detailed assessment deeply explores the facts about the product, price change over the weeks, months, and years, key players, industrial uses, and drivers propelling the market and price trends.

Each price record is linked to an easy-to-use graphing device dated back to 2014, which offers a series of functionalities; customization of price currencies and units and downloading of price information as excel files that can be used offline.

The Steel price trend, pricing database, and analysis can prove valuable for the procurement managers, directors, and decision-makers to build up their strongly backed-up strategic insights to attain progress and profitability in the business.

Industrial Uses Impacting Steel Price Trend:

The largest and most significant demand for steel is in the building sector. The reason for this is that steel has various benefits in the construction sector. Steel is the most resilient metal there is. Iron, carbon, manganese, nickel, and phosphorus are the main components of steel.

The largest and most significant demand for steel is in the building sector. The reason for this is that steel has various benefits in the construction sector. Steel is the most resilient metal there is. Iron, carbon, manganese, nickel, and phosphorus are the main components of steel.

In most cases, high-quality, rust- and corrosion-resistant steel is needed for bridge building. Due to its adaptability, strength, and ductility, steel is the most frequently utilised material in bridge construction since it allows for the support of both static and dynamic loads.

One of the biggest consumers of steel and steel plates is the transportation sector. The most adaptable material for a ship's interior and exterior is steel. Propellers, oil tankers, rudder pintles, watertight doors on passenger ships, and container ships are all made of steel. Steel makes up the bogies, the framework that supports the trains' wheels, axles, bearings, and motors.

Steel aids automakers in creating vehicles with the right strength and design. In order to improve tensile strength, steel that contains chromium, manganese, vanadium, and tungsten is utilised in the automobile sector. This steel's high resistance to mechanical pressure makes it ideal for use in the construction of automotive bodywork. Modern high-strength steel is most frequently employed in the automotive industry.

Key Market Players:

• ArcelorMittal S.A

• Hindustan Steel Corporation (LTD.)

• Tata Steel Limited

• Nippon Steel Corporation

News and Events:

• September 23, 2022: Steel manufacturers across the EU have reduced their output as a result of rising energy prices, which has increased the possibility of plant closures (both temporary and permanent) in a sector that employs some 300,000 people and contributes tens of billions of euros to the regional economy.

Related Reports:

- Steel Rebar Price Trend - https://www.procurementresource.com/resource-center/steel-rebar-price-trends

- Steel Scrap Price Trend - https://www.procurementresource.com/resource-center/steel-scrap-price-trends

- Steel I Beam Price Trend - https://www.procurementresource.com/resource-center/steel-i-beam-price-trends

About Us:

Procurement Resource offers in-depth research on product pricing and market insights for more than 500 chemicals, commodities, and utilities updated daily, weekly, monthly, and annually. It is a cost-effective, one-stop solution for all your market research requirements, irrespective of which part of the value chain you represent.

We have a team of highly experienced analysts who perform comprehensive research to deliver our clients the newest and most up-to-date market reports, cost models, price analysis, benchmarking, and category insights, which help in streamlining the procurement process for our clientele. Our team tracks the prices and production costs of a wide variety of goods and commodities, hence, providing you with the latest and consistent data.

To get real-time facts and insights to help our customers, we work with a varied range of procurement teams across industries. At Procurement Resource, we support our clients, with up-to-date and pioneering practices in the industry, to understand procurement methods, supply chain, and industry trends, so that they can build strategies to achieve maximum growth.

Contact Us:

Company Name: Procurement Resource

Contact Person: Jolie Alexa

Email: sales@procurementresource.com

Toll Free Number: USA & Canada – Phone no: +1 307 363 1045 | UK – Phone no: +44 7537 132103 | Asia-Pacific (APAC) – Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USs