| Report Features | Details |

| Product Name | Sodium Hydroxide |

| Industrial Uses | Personal Care, Pharmaceutical, Pulp & Paper, Textile |

| Chemical Formula | NaOH |

| Supplier Database | The DOW Chemical Company, BASF SE, Ciech S.A., Gujarat Alkalies and Chemicals Limited, Kemira Chemicals, Inc., Shandong Haihua Group Co., Ltd., INEOS Newton Aycliffe Ltd., Solvay Chemicals |

| Region/Countries Covered | Asia Pacific: China , India, Indonesia, Pakistan, Bangladesh, Japan, Philippines, Vietnam, Iran, Thailand, South Korea, Iraq, Saudi Arabia, Malaysia, Nepal, Taiwan, Sri Lanka, UAE, Israel, Hongkong, Singapore, Oman, Kuwait, Qatar, Australia, and New Zealand Europe: Germany, France, United Kingdom, Italy, Spain, Russia, Turkey, Netherlands, Poland, Sweden, Belgium, Austria, Ireland Switzerland , Norway, Denmark, Romania, Finland, Czech Republic, Portugal and Greece North America: United States and Canada Latin America: Brazil, Mexico, Argentina, Columbia, Chile, Ecuador, and Peru Africa: South Africa, Nigeria, Egypt, Algeria, Morocco |

| Post-Sale Analyst Support | 360-degree analyst support after report delivery |

| Customization Scope | The report can be customized as per the requirements of the customer |

Request for Real Time Sodium Hydroxide Prices: https://www.procurementresource.com/resource-center/sodium-hydroxide-price-trends/pricerequest

Sodium hydroxide, which is also referred to as lye or caustic soda, is an inorganic substance. Sodium hydroxide is a crystalline solid that melts without decomposing at 318 °C or 604 °F and boils at 388 °C or 2,530 °F. At standard room temperature, sodium hydroxide, an extremely caustic base and alkali, break down proteins. It easily takes in moisture and CO2 from the air and is extremely miscible in water. However, ether and other non-polar solvents do not allow for their solubility.

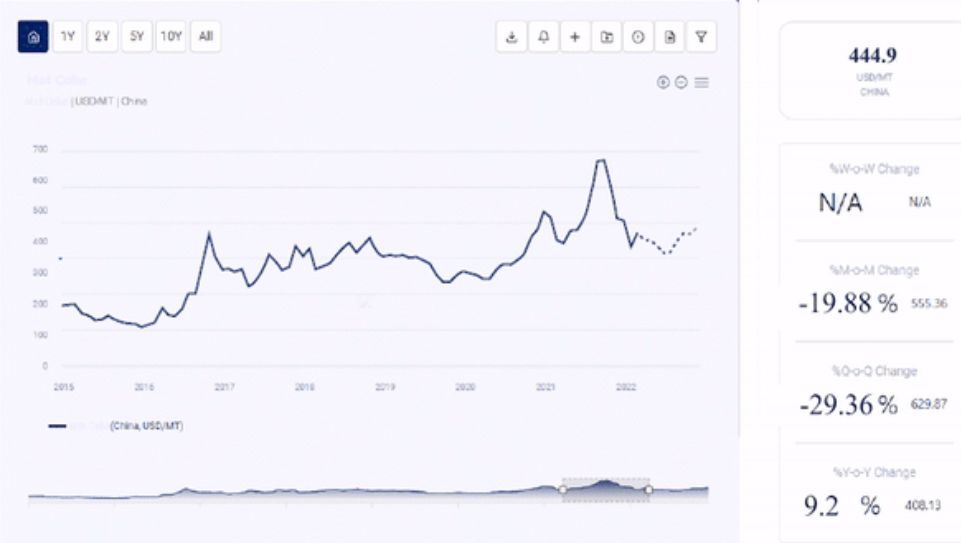

The largest producer and largest consumer of caustic soda are China and is followed by India, Poland, and Russia.

Key Details About the Sodium Hydroxide Price Trend:

Procurement Resource does an in-depth analysis of the price trend to bring forth the monthly, quarterly, half-yearly, and yearly information on the sodium hydroxide price, carbon black price and lithium carbonate price etc. in its latest pricing dashboard. The detailed assessment deeply explores the facts about the product, price change over the weeks, months, and years, key players, industrial uses, and drivers propelling the market and price trends.

Each price record is linked to an easy-to-use graphing device dated back to 2014, which offers a series of functionalities; customization of price currencies and units and downloading of price information as excel files that can be used offline.

The sodium hydroxide price trend, pricing database, and analysis can prove valuable for procurement managers, directors, and decision-makers to build up their strongly backed-up strategic insights to attain progress and profitability in the business.

Industrial Uses Impact Sodium Hydroxide Price Trend:

The packaging, agricultural, paper, pulp, water treatment, textiles, chemicals, construction, and auto industries are the main industrial applications of sodium hydroxide that have an impact on its price trend. Sodium hydroxide is also used in glass production and mining.

Key Market Players:

• The DOW Chemical Company,

• BASF SE,

• Ciech S.A.,

• Gujarat Alkalies and Chemicals Limited,

• Kemira Chemicals, Inc.,

• Shandong Haihua Group Co., Ltd.,

• INEOS Newton Aycliffe Ltd., Solvay Chemicals

News and Events:

• January 2021: The Indian company, Andhra Sugars, announced plans to boost the production of caustic soda from 500TPD to 900TPD.

• January 2021: The capacity of Shin-Etzu Chemical Co. decided to produce caustic sodaby an increment of 390,000 m.t. per year.

Related Reports:

- Silicone Emulsion Price Trend - https://www.procurementresource.com/resource-center/silicone-emulsion-price-trends

- Sodium Chlorate Price Trend - https://www.procurementresource.com/resource-center/sodium-chlorate-price-trends

- Sodium Chlorite Price Trend - https://www.procurementresource.com/resource-center/sodium-chlorite-price-trends

About Us:

Procurement Resource offers in-depth research on product pricing and market insights for more than 500 chemicals, commodities, and utilities updated daily, weekly, monthly, and annually. It is a cost-effective, one-stop solution for all your market research requirements, irrespective of which part of the value chain you represent.

We have a team of highly experienced analysts who perform comprehensive research to deliver our clients the newest and most up-to-date market reports, cost models, price analysis, benchmarking, and category insights, which help in streamlining the procurement process for our clientele. Our team track the prices and production costs of a wide variety of goods and commodities, hence, providing you with the latest and consistent data.

To get real-time facts and insights to help our customers, we work with a varied range of procurement teams across industries. At Procurement Resource, we support our clients, with up-to-date and pioneering practices in the industry, to understand procurement methods, supply chain, and industry trends, so that they can build strategies to achieve maximum growth.

Contact Us:

Company Name: Procurement Resource

Contact Person: Chris Byrd

Email: sales@procurementresource.com

Toll Free Number: USA & Canada – Phone no: +1 307 363 1045 | UK – Phone no: +44 7537 132103 | Asia-Pacific (APAC) – Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA